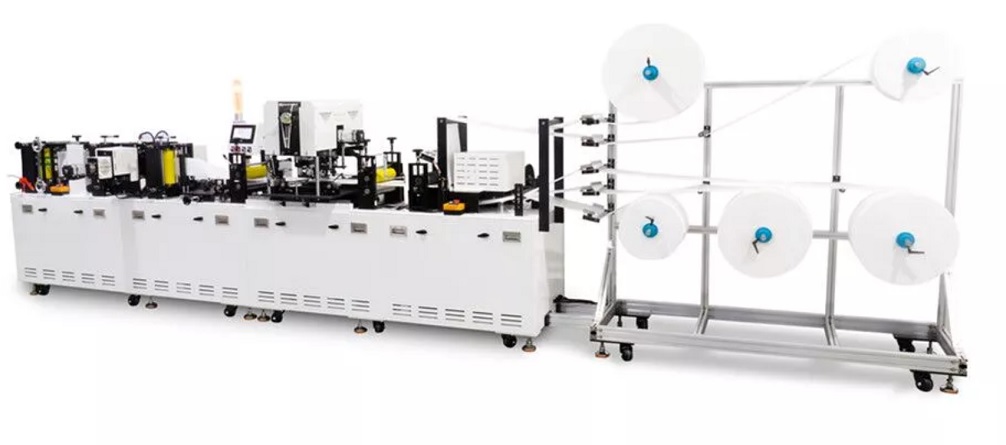

FFP2 mask manufacturing machines – Mask Folding Machine

The KN95 nose mask FFP2 mask manufacturing machines are mainly used for fully automated folding mask production. The N95 mask manufacturing machine can produce masks in large quantities with ease.

This machine has a high production speed of 100 n95 masks, kn95 masks, and FFP2 masks per minute. Mask folding machine (KN95, FFP2) uses ultrasonic technology to automate and generate 4-5 layers of KN95 masks at a speed of 100 pieces per minute, saving you and your team time and labor.

The mask production machine’s innovative design may be used to make varied quality earloops, and it runs smoothly without stuttering or jamming. At the same time, the mold can be replaced to adapt to the manufacture of various N95/KN95/FFP2 masks in order to fulfill market demand.

This machine is primarily used for the automatic forming of three-dimensional masks: after being unrolled, the entire roll of fabric is driven by the roller, and the fabric is unrolled through the entire roll of the nose bridge, cut to a fixed length, imported into the hemming fabric for welding, integral forming and welding, and then passed through the ears.

According to customer requirements, the fully automatic mask production line can be connected to the coding machine, mask packaging machine, mask inkjet printer, mask cartoning machine, deviation correction controller, magnetic powder air shaft feeding rack, etc. to complete the full set of functions such as mask surface coding, mask plastic film packaging, mask carton packaging, carton coding, and so on.

How it Works

- The following is the procedure for using N95 Mask Machines:

- After input, the multi-layer non-woven fabric rolls are subjected to compound roll welding.

- After unrolling and cutting, the nasal lines are welded together.

- After mechanically unrolling and cutting two rolls of rubber band to the desired length, they are welded together.

- After that, the masks are folded in half.

- The masks are then rolled-cut and manufactured after ultrasonic welding and fusion.

- Finally, the N95 masks are ready.

Why N95 Masks?

The N95 masks have a good filtration efficiency, they fit people’s faces well, and they are easy to use without exerting any pressure. The masks can be used in a variety of fields, including medicine, electronics, mining, and construction.